Hard Metals Zinc Standing Seam for Roofing and Cladding

We are working with Metal Solutions (the UK’s leading supplier & fabricator of all traditional metal roofing systems, cladding systems and components) and their Manufacturers to offer a variety of Hard Metals. We have a wide range of products in stock that include Zinc, Aluminium and Steel in coils, with other products available within a few days.

The aesthetics each supplier has created gives a distinctive character to each project, and depending on the manufacturer the finishes can offer subtle changes (any natural products such as zinc and copper can change slightly throughout its lifetime).

We have samples available on request and the chance to meet with out suppliers representatives to go over their full range.

There are other products that we are also able to offer to help meet any fire regulations for roofing and cladding, these products include non-combustible substrates such as Trapezoidal steel deck sheets TATA D32 or D35 as well as Euroclass A1 Magply cement board which has been tested to EN 13501 Class A1 Non-combustible in-line with building control.

Brands

Metal Solutions

Metal Solutions offer products which include 600mm wide coils as well as Iso Mat Metal® Underlay, Iso Mat Pro® Underlay, Fixed and Sliding clips and Flux solder. Other sizes and products are available on request. (0.6mm, 0.7mm, 0.9mm, 1mm, 1.5mm, 2mm) (500mm, 670mm, 1000mm)

These Hard Metals are used for Traditional Standing Seam for roofing and cladding (facades) but can be used for Interlocking panels and shingles too.

Special fabrications are also available for capping, shingles, guttering and downpipe.

ISO-Mat Metal®

ISO-Mat Metal® is a condensation and drainage system used for metal roofing, incorporating a breathable membrane base with an additional layer of spiralled polypropylene mesh melt bonded to it. It has been designed as a moisture and separation layer for all types of standing seam and metal roofs. ISO-Mat Metal® is a strong, fully vapour permeable, durable and waterproof barrier, which is available in 25m x 1m rolls.

Iso-Mat Metal Underlay

ISO-Mat Pro® Underlay

ISO-Mat Pro® is used in roofing and cladding application as a high performance breather membrane and underlay, suitable for all types of commercial and domestic buildings. Suitable as an underlay in all UK wind zones as described in BS 5534. Available in 50m x 1m rolls.

Iso-Mat Pro Underlay

Hard Metal Board (HMB)

Hard Metal Board is a warm roof substrate suitable for copper, zinc, aluminium, coated steel and stainless steel roofing systems. It is a high performance, rigid polyisocyanurate insulation board with Tongue and Groove joint. On the upper side, it is faces with an 18mm OSB3 sheet whilst on the rear, with a gas tight multi-layer aluminium facing.

| Total thickness | Length | Width |

| 68mm (50mm + 18mm) | 1160mm | 1160mm |

| 88mm (70mm + 18mm) | 1160mm | 1160mm |

| 98mm (80mm + 18mm) | 1160mm | 1160mm |

| 108mm (90mm + 18mm) | 1160mm | 1160mm |

| 118mm (100mm + 18mm) | 1160mm | 1160mm |

| 128mm (110mm + 18mm) | 1160mm | 1160mm |

| 138mm (120mm + 18mm) | 1160mm | 1160mm |

| 148mm (130mm + 18mm) | 1160mm | 1160mm |

| 158mm (140mm + 18mm) | 1160mm | 1160mm |

| 168mm (150mm + 18mm) | 1160mm | 1160mm |

Hard Metal Board

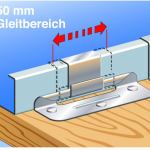

Thermoseam Warm Roof Clip

The Thermoseam TS25 warm roof clip has been designed specifically for the installation of traditional standing seam roofing, laid direct on insulation. It is important that an air-tight vapour barrier is used in warm roof constructions. The clip is currently available with a range of thermal breaks for insulation depths up to 255mm.

- Pullout Value: 820N

- Base: 0.6mm

- Strap: 0.4mm

- Free movement: 40mm

- Insulation thickness: up to 255mm

- Includes clip and peg (fixing excluded).

In stock: 90mm.

Available in: 50mm, 90mm, 130mm and 190mm.

Thermoseam Clip

S5! Seam Clamps and PV Kits

S-5! are the market leaders in seam clamps and PV kits for metal roofs. In most cases, the savings in time and materials is sufficient to pay for the entire S-5 PV Kit and clamp setup. The easiest, most cost-effective way to install solar panels directly to standing seam metal roofs.

S-5 PV Kit

S-5 Mini Clamp

Snow Guard System for Metal Roofing

Snow and ice guards prevent the dangerous movement of snow and ice on metal roofs, which can cause damage to anything below. The snow guard system is easy to fix and is suitable for new installation or as a retrofit. All traditional 25mm / 35mm standing seam metal roofs including copper alloys, zinc, stainless steel, coated aluminium, aluminium and coated steel can be accommodated.

Snow Guard System

SM System Snow Guard Clamp

RAKU Topclip Parapet Capping Joint

The Topclip joint is a method of joining cappings, copings, ridges, roof edges, window sills and cornice flashings. It is suitable for all current metals, including copper, zinc, stainless steel and aluminium. The Topclip is easy to fix and doesn’t require soldering, sealing, special skills or expansion joints. The open joint guarantees expansion / contraction without any restriction. The joint has a standard length 3000m and is cut to length and folded as required, with the double vulcanised rubber strip attached to either 1.2mm aluminium or 0.8mm stainless steel (for use with copper).

Topclip Capping Joint Concept Video

Topclip Capping Joint Installation Video

RAKU Topclip Capping

RAKU Topclip Joint

Traditional Metal Roofing Tools & Cladding Supplies

Standing Seam Sliding Clip (400nr)

In boxes of 400.

Available in 25mm, 30mm and 38mm.

In stock: 25mm and 30mm.

Standing Seam Sliding Clip

Tinmans Solder Stick

Leaded solder sticks, suitable for jointing copper, zinc and stainless steel.

Technical Information

- Grade: G

- Content: 40% tin / 60% lead

- Length: 400mm

- Weight: 0.25kg

Tinmans Solder Stick

Paslode IM45 25mm Stainless Nail & Fuel Pack

2.88mm full head nails in length 25mm.

Includes:

- 1000nr nails.

- 1nr gas fuel cell.

Features & Benefits

- Unique full head design offers optimum performance and the best quality finish for metal roofing applications.

- Best collation in class: no material trapped under the head providing highest quality fixing.

- High load capacity: work longer without reloading.

- Reliable system: use every nail & in every coil eliminate waste.

- Safe system: Paslode 0° system eliminates wire flagging & stinging debris.

Technical Information

- Tensile strength wire: minimum 700N/mm²

- Diameter, shank: 2.8mm

- Diameter, profile minimum: 2.9mm

- Total nail length: 25mm

- Shank: Ring

- Finish: Stainless steel

- Fuel cell capacity: 1000 shots

Paslode Pack

Paslode Fuel Pack

Paslode Nails

Stainless Steel Ring Shank Nails 25mm (5kg)

Stainless steel annular ring shank nails.

Size: 25mm long x 3.35mm diameter.

Quantity: approx. 2500nr.

Box size: 5kg.

Available in 20mm, 25mm, 40mm and 65mm.

Ring Shank Nail

Stainless Screw for Plywood / OSB

To fix to timber (i.e. plywood or OSB).

Length: 20mm

Shank: 4.3mm

Boxes of 1000nr.

Available in 20mm, 25mm and 30mm.

Stainless Screw

NedZink Zinc

NedZink has already been producing high quality zinc products for applications in the construction sector for more than a hundred years. Titanium zinc is sold under the brand names NedZink NATURAL, NedZink NOVA, NedZink NOIR, NedZink NUANCE, NedZink Pro-Tec and NedZink NOVA COMPOSITE and has an excellent reputation on the international market. The basic material NedZink NATUREL is titanium zinc with a smooth rolled surface for applications in roof and façade cladding, roof gutters and rainwater drainage systems.

NedZink Coils are available in widths of 150 – 1000mm and the material thickness can range between 0,65 – 0,70 – 0,80 – 1,00 mm. The NedZink Sheets have standard sizes of 1000 x 2000mm, 1000 x 2250mm and 1000 x 3000mm, with materials thickness the same as the coils above.

Sample packs are available upon request, please contact use for more information.

NedZink NATUREL

NedZink NATUREL is a durable, aesthetic and maintenance-free building material that becomes increasingly attractive over the years under the influence of the weather conditions. A natural zinc patina layer forms on the surface. This property means NedZink NATUREL is mainly used where a natural and lively appearance, high cost-effectiveness and a long life are required.

NATUREL

NedZink NATUREL

NedZink NEO

NedZink NEO is pre-weathered titanium zinc with a matte, subtle brushed surface in a mineral grey colour. The uniform mineral grey surface of NedZink NEO originates after a chemical surface treatment following the rolling process. No coating or lacquer layer is applied. The structure and composition of the patina layer that is normally naturally formed by weather influences is simulated, and the natural properties of the titanium zinc are fully retained.

Mineral Grey

NedZink NEO

NedZink NOVA

NedZink NOVA is pre-weathered titanium zinc with a matte, subtle brushed surface in a natural medium-grey colour. The uniform medium-grey surface of NedZink NOVA originates after a chemical surface treatment following the rolling process. No coating or lacquer layer is applied. The structure and composition of the patina layer that is normally naturally formed by weather influences is simulated, and the natural properties of the titanium zinc are fully retained.

The Conservation product range consists of the following: Conservation Red, Conservation Weathered, Conservation Brown, Conservation Dark.

Natural Grey

NedZink NOVA

NedZink NOIR

NedZink NOIR is pre-weathered titanium zinc in an anthracite black colour. NedZink NOIR is created by a chemical surface treatment after the milling process. All the characteristics of zinc titanium are fully retained. NedZink NOIR is beside NedZink NOVA a second colour variant of pre-weathered zinc titanium.

NedZink NOIR

Anthracite Black

NedZink NUANCE

NedZink NUANCE is pre-weathered titanium zinc provided with pigments. This results, depending on the selected pigment, in a pre-weathered zinc variant with a blue, red or green colour nuance. The natural properties of titanium zinc; high durability, maintenance-free and good deformation properties are fully retained. NedZink NUANCE is mainly used for aesthetically high quality building applications: outside for roofs and façades or inside for various design applications.

NedZink NUANCE

Green, Red, Blue

NedZink COMPOSITE

NedZink NOVA COMPOSITE is a panel consisting of two layers of preweathered zinc ‘NedZink NOVA’ and a LDPE core. This combination creates a stiff and flat panel which is perfect for cladding applications. Gluing, cassettes, clamping or screwing, for any application a solution is available. With a layer of polyethylene between two layers of zinc, NedZink NOVA COMPOSITE can easily be used as a cassette. Self-coloured, rigid and extremely stable – enabling untold applications of zinc.

NedZink COMPOSITE

COMPOSITE

NedZink Pro-Tec

NedZink Pro-Tec is process-produced titanium zinc with a protective coating on the backside for application on either cold or damp-proof constructions. The protective layer protects the zinc against the effects of water vapor and other substances. The effective processing properties offered by zinc are retained. NedZink Pro-Tec can be used in all standard systems, but is mainly recommended for unventilated, damp-proof hot roof constructions and outer wall cladding.

NedZink Pro-Tec is available in the following versions:

- NedZink NATUREL Pro-Tec

- NedZink NEO Pro-Tec

- NedZink NOVA Pro-Tec

- NedZink NOIR Pro-Tec

- NedZink NUANCE Pro-Tec

NedZink Pro-Tec

Pro-Tec

Traditional Textures Aluminium

Metal Solutions Ltd have introduced a range of precoated aluminium that captures the colour pigments and textures of real zinc and copper cladding, available in coil form or pre-fabricated into roofing / cladding components such as standing seam / Snaplock® profiles, interlocking panels, shingles, rainwater goods etc.

They hold a realistic and aesthetically pleasing finish, being much more cost-effective than the more expensive materials. Precoated aluminium is a flat rolled product with an aluminium core protected by a special coating. It has a long life, is lightweight, is easy to work and is eco-friendly.

Warranties are available on a prior project basis, up to 20 years on the base metal & coating. Precoated aluminium can be produced in any RAL colour as well as many other specialist finishes.

Traditional Textures Precoated Aluminium Brochure

Please contact us for more information.

Zinc Patina Finishes

Zinc Patina

Graphite Patina

Dark Zinc Patina

Red Zinc Patina

Blue Zinc Patina

Green Zinc Patina

Copper and Corten Finishes

Copper Metallic

Copper Oxide

Copper Patina

Corten

Other Pre-Coated Aluminium Finishes

Anthracite (RAL 7016)

Inca Gold

Natural (Uncoated)

Greencoat PLX SSAB Colour Coated Steel

GreenCoat® is the brand for innovative, sustainable colour coated steel solutions for roofs, façades and rainwater systems. Widely used in sustainable architecture, GreenCoat® products offer an extensive range of colours and coatings with Swedish rapeseed oil.

The unique, patented BT coatings (Bio-based Technology) offer environmental advantages, as well as increased performance. GreenCoat products are highly resistant to corrosion, scratches and UV radiation. This lightweight material is easy to work with, even at temperatures as low as -15 degrees C.

GreenCoat PLX was developed alongside Swedish metal roofers over 50 years ago. It consists of Nordic quality steel in the core with a zinc anti-corrosion coating, followed by a primer. The top coating (containing Swedish rapeseed oil) gives the material its final colour.

As a high-quality metal roofing and cladding material, GreenCoat PLX can be used fully supported standing seams, shingles and reveal panels. Used extensively throughout Europe and Sweden, it can withstand harsh climates where summers are warm and winters very cold.

GreenCoat PLX has no spring-back, allowing very tight folding. The high strength and guaranteed long-life of GreenCoat PLX ensures that it is an excellent alternative. It can be used for industrial, commercial, residential or renovation applications where factors such as appearance, mechanical resistant, fire safety and long-life are important.

GreenCoat PLX Colour Brochure

GreenCoat PLX Installation Guide

GreenLine® Rainwater System Leaflet

GreenCoat Product Program for the Building Industry – Outdoor Exposure

We have a wide range of GreenCoat PLX colours available. Contact us for your GreenCoat sample today!

GreenCoat PLX Pural BT Finishes

Pural BT Nordic Night Black

Pural BT Mountain Grey

Pural BT Anthracite Grey

Pural BT Metallic Dark Silver

Pural BT Metallic Silver

Pural BT Quarry Grey

Pural BT Snow White

Pural BT Metallic Gold

Pural BT Metallic Copper

Pural BT Chestnut Brown

Pural BT Cottage Red

Pural BT Tile Red

Pural BT Leaf Green

Pural BT Silver Fir Green

GreenCoat PLX Pro BT Finishes

Pro BT Nordic Night Black

Pro BT Mountain Grey

Pro BT Anthracite Grey

GreenCoat S280 Pural BT Finishes (Reveal Panel etc)

S280 Pural BT Nordic Night Black

S280 Pural BT Mountain Grey

S280 Pural BT Metallic Dark Silver

Falzonal Aluminium

Falzonal is a precoated rolled aluminium product designed to deliver superior results for roofing. Semi-finished and coil-coated, the mechanical properties of the alloy and the coating were developed specifically for double standing seam.

The PVdF coating provides superior resistance to UV light, sea water, and corrosion due to condensation.

In terms of alloy, strength and coating, this colour aluminium strip has been specially tailored for applications using sheet metal techniques. It is perfectly suited to the widest variety of folding techniques – and can be combined with materials such as wood, glass or steel.

Falzonal is available in a wide range of colours and surfaces with plain or metallic colours including copper, zinc or titanium shades.

Falzonal Finishes

Anodic Brown

Anthracite

Azure Blue

Bright Metallic

Broom Yellow

Carbon Black

Coffee Brown

Copper Brown

Crimson

Dusty Blue

Gentian Blue

Grey Aluminium

Grey Green

Light Bronze

Light Grey

Light Ivory

Matt Dark

Matt Light Grey

Matt Light Zinc

Maya Gold

Mint Green

New Copper

Olive Green

Opal Green

Pastel Turquoise

Pearl White

Pure White

Quartz Zinc

Reseda Green

Savannah Beige

Tin Grey

Turquoise Blue

Victorian Brick Red

Weathered Clear Varnish

Zinc Grey

ZM Silesia Zinc

ZM Silesia Zinc is produced according to EN988 in the following three finishes:

- Bright Rolled (Natural) – Initial bright surface which quickly forms a light grey patina (under localised atmospheric conditions).

- Pre-aged Grey – Mat light grey patina surface, chemically created to represent weathered zinc. It is recommended to use pre-aged material on elements such as facades.

- Pre-aged Carbon – Mat dark grey patina surface, chemically created to represent dark weathered zinc. The contrasting dark patina provides a distinctive identity whilst harmonising with other building materials such as slate.

ZM Silesia Zinc-titanium is a modern material produced from the highest purity zinc SHG 99.995% with additions of copper and titanium. Modern technology guarantees very good physical and mechanical properties and allows for wide range of application in building industry.

It is durable for over 80 years, corrosion resistant, does not require maintenance, may be easily formed and jointed, excellent for soldering, light and non-flammable and 100% recyclable.

ZM Silesia Zinc has a standard 30 year warranty.

Please contact us today for more information or sample packs.

Bright Rolled (Natural)

Pre-Aged Grey

Pre-Aged Carbon

Roofinox Stainless steel 316L

Roofinox AG has been supplying the roof and façade specialists with the highest quality rust-free stainless steel for over 30 years. Roofinox stainless steel has been specially developed for use on the building envelope and can be found on roofs, facades and in the building’s drainage.

Roofinox stainless steel is made in their factory in Germany, made from approximately 85% recycled material and is itself 100% recyclable. Roofinox stainless steel is available in a variety of surface designs, offers an unbeatable life-span and is virtually free of maintenance.

Roofinox was the first matt-finished brand name stainless steel on the market in 1999 and established itself very quickly.

Roofinox Tin-matte Stainless Steel

The popular traditional metal for optically appealing and very long lasting roofs is also frequently used to restore historic roofs, for beauty and also great durability. It is therefore perfect for modern roofs for exactly the same reasons. Tin matte metal roofs go well with timer facades as both weather to natural grey tones, which produces an organic, aesthetic look.

The weathering process takes around 2 to 3 years. Roofinox Tin-matte is typically used on roofs due to the number of builders who do not want a naturally unequal patination, where on the façade this would be impossible to influence.

Roofinox Tin Matte

Roofinox Classic

To accommodate the growing trend of matt surfaces in architecture, the Roofinox Classic surface has been developed, achieving a special light distribution leading to an exquisite matt finish (i.e. very low degree of reflection).

The Roofinox Classic structure is rolled in, making it much more resistant to corrosion and results in an 88% lower gloss level than a standard stainless steel. At the same time, the mechanical properties of the building envelope have been optimized, making Roofinox Classic the preferred material for the craftsman.

Roofinox Classic

Roofinox Stainless Steel Surfaces

Architects and builders are increasingly taking advantage of the many functional and optical advantages of stainless steel surfaces for the roof and façade. All Roofinox stainless steel surfaces are specially created design surfaces. Each one has been designed to meet specific functional and aesthetic requirements.

Zintek Zinc

Zintek presents six colours that emphasise the nature of zinc-titanium zintek whilst maintain its excellent properties.

INNOVATION

Zintek has launched a line of coloured zinc obtained with a pigment colouring process that offers a wide range of possibilities for architectural applications.

TECHNOLOGY

The colours have been developed to highlight the aesthetic quality of Zintek, while maintaining its technical and functional characteristics.

VERSATILITY

Zintek colours are ideal for architecture and interior design, and they give originality to every project, in full coherence with the environment.

Colours – Lagoon Green, Mediterranean Blue Antique Red, Natural Earth Brown, Rock Grey and Graphite Black.

Mediterranian Blue

Lagoon Green

Graphite Black

Rock Grey

Natural Earth Brown

Antique Red

Prefa Aluminium

PREFA produce a wide variety of coated aluminium for roofing & façade, along with rainwater goods ad all possible roofing and façade accessories.

PREFALZ is a pre-painted aluminium coil in a variety of aesthetically pleasing finished, which is specially produced for the fully supported metal roofing and façade market. PREFALZ is available in coil form for site installation or for manufacture into cladding panels / roofing accessories. Prefalz® is more pliable than most comparable folding materials.

PREFA products are available pre-fabricated into roofing and façade components such as standing seam / Snaplock® profiles, interlocking panels, cassette panels, shingles, rainwater goods etc.

Recommendation: plan a minimum substructure roof pitch of > 7º (13%). Roof pitch from 3° (according to the information/limitations of ÖNORM B 3521-1), > 7° recommended (see planning guide).

A 40 year warranty is available on the base material for all products and for the P10 (textured) finishes.

Advantages of Prefalz® include:

- Comprehensive PREFA system accessories

- Versatile use – from arched roofs to complex roof extensions, domes or large-scale roofs

- Colour chart with 19 standard colours

- Available with smooth or stucco surface

- Low weight sheet strip: 1.89 kg/m²: approx. 2.3 kg/m² roof surface with Prefalz® 500, approx. 2.2 kg/m² roof surface with Prefalz® 650

- Long service life – non-corrosive!

- Fully recyclable

- Also available with protective film on request (smooth surface only)

- Easy to work with even in low outdoor temperatures

- Easy to work with, strong load-bearing capacity

- Alloy, mechanical properties and coating are coordinated with the folding technology

- No heavy metal erosion

- Prefalz® is non-combustible (A1)

Prefa Roofing Brochure

Prefa Façade Brochure

Prefa Rainwater Goods Brochure

Contact us today for brochures, samples, swatches and current pricing.

Oxide Red P10 (05)

Brick Red P10 (04)

Black P10 (03)

Anthracite P10 (02)

Brown P10 (01)

Nut Brown P10 (11)

PREFA White P10 (10)

Zinc Grey P10 (08)

Light Grey P10 (07)

Moss Green P10 (06)

Plain Aluminium (13)

Metallic Silver (12)

Stone Grey P10 (43)

Dark Grey (19)

Pure White P10 (17)

Patina Grey (47)

Patina Green P10 (46)

Bronze (45)

Black Grey (23)

Aurubis Copper

Aurubis has developed a range of factory applied surface treatments to provide straightaway the various stages of oxidisation and patination. The processes involved are very similar to those taking place over time in the environment and utilise copper mineral compounds, rather than alien chemical treatments. Essentially, they bring forward the environmental changes without removing the integrity of Aurubis copper as a natural, living material.

The natural development of copper patina is one of copper’s unique characteristics. Within a few days of exposure to the atmosphere, the surface of Nordic Standard copper begins to oxidize, changing its color from the “bright” mill finish to a chestnut brown which gradually darkens over several years to a chocolate brown. Continued weathering can then result in development of the distinctive green patina – or blue in coastal locations. The patina film provides remarkable protection against corrosion and can repair itself if damaged, defining the exceptional longevity of copper cladding.

Nordic Standard

Nordic Standard is mill finish copper without any additional surface treatments carried out in the factory. It has the traditional ‘bright’ finish that will develop and change in the environment.

| Product | Alloy | Thickness range mm | Maximum width mm |

| Nordic Standard | Cu-DHP | 0.3-4.0 | 1,100 mm |

Shapes: Sheet, coil.

(Other dimensions on request).

Nordic Standard

Nordic Brown

Nordic Brown products are pre-oxidised at Aurubis’ factory to provide the same oxidised brown surface that otherwise develops over time in the environment. The thickness of the oxide layer determines the colour: Nordic Brown Light and the darker Nordic Brown versions are available. Nordic Brown products are useful to minimise the hand and other construction marks which may occur for a short time after installing ‘bright’ standard copper. Also, light and dark versions can be combined – perhaps with other finishes such as Nordic Standard – to create various visual effects.

| Product | Alloy | Thickness range mm | Maximum width mm |

| Nordic Brown & Nordic Brown Light | Cu-DHP | 0.5-1.5 | 1,000 mm |

Shapes: Sheet, coil.

(Other dimensions on request).

Nordic Brown

Nordic Green and Nordic Blue

Nordic Green and Nordic Blue products offer designers design freedom and the ability to determine the type and intensity of green or bluish patina for each project with choices of ‘Living’ surfaces.

The factory process can be accurately controlled so that other intensities of patina flecks can be created, revealing some of the dark oxidised background material. Special individual levels of patination can be developed to meet the design requirements to match historically patinated copper in existing buildings.

The material is easily bent and formed, with no limitations on the length of pre-patinated copper sheet or strip, as the whole coils are treated on the production line, not just limited size sheets. Just like natural patina, Nordic Green and Nordic Blue undergo continuous changes through environmental exposure dependent upon local atmospheric and rainfall conditions.

- Mineral-Based Green

The most common compound found in natural patinas all over the world is copper sulfate mineral brochantite. Brochantite is a light blue colour, however many locations impurities and other components in the air add a yellow tint to give the naturally developed patina a green hue. Similarly, Nordic Green is produced with a hint of iron sulfate yellow component added to the blue copper sulfate, replicating the natural green. - Mineral-Based Blue

In marine climates, the natural cooper patina contains come copper chloride, giving it more of a blue colour, emulated with the Nordic Blue. Brochantite is a light blue colour and Aurubis’ Bordic Blue patination is 100% brochantite.

| Product | Alloy | Thickness range mm | Maximum width mm |

| Nordic Green & Nordic Blue | Cu-DHP | 0.5-1.5 | 1,000 |

Shapes: Sheet, coil.

(Other dimensions on request).

Nordic Green and Blue

Mineral-Based Green

Mineral-Based Blue

Nordic Brass

Nordic Brass is an alloy of copper and zinc with a distinctive golden yellow colour. When exposed to the atmosphere, the surface begins to darken within weeks and can change to a dark brown in around a year – unlike Nordic Royal™ alloy which retains its original colour. A weathered brownish surface is also available to provide the same oxidised brown surface that otherwise developed over time in the environment.

| Product | Alloy | Thickness range mm | Maximum width mm |

| Nordic Brass & Nordic Weathered | CuZn15 | 0.5-2.0 | 1,000 |

| Nordic Brass 30 | CuZn30 | 0.5-2.0 | 1,000 |

Shapes: Sheet, plate.

(Other dimensions on request).

Nordic Brass

Nordic Bronze

Nordic Bronze is an alloy of copper and tin with a similar colour to Nordic Standard initially. When exposed to the atmosphere, the surface gradually changes to a reddish dark brown to a black shade.

| Product | Alloy | Thickness range mm | Maximum width mm |

| Nordic Bronze | CuSn4 | 0.5-2.0 | 780 |

Shapes: Sheet, coil.

(Other dimensions on request).

Nordic Bronze

Nordic Royal

Nordic Royal™ is an alloy of copper with aluminium and zinc, giving it a rich golden through-colour that changeably incorporates a matte, golden-brown surface. It has a thin protective oxide layer containing all three alloy elements when produced. As a result, the surface retains its golden colour and simply loses some of its sheen as the oxide layer thickens with exposure to the atmosphere to give a matt finish.

It behaves differently from other Aurubis cooper products over time and does not develop a blue or green patina. Exceptional cases are coastal and humid regions.

| Product | Alloy | Thickness range mm | Maximum width mm |

| Nordic Royal™ | CuAl5Zn5Sn1 | 0.5-1.5 | 1,000 |

Shapes: Sheet, coil.

(Other dimensions on request).

Nordic Royal